-

Aluminum Alloy Casting

-

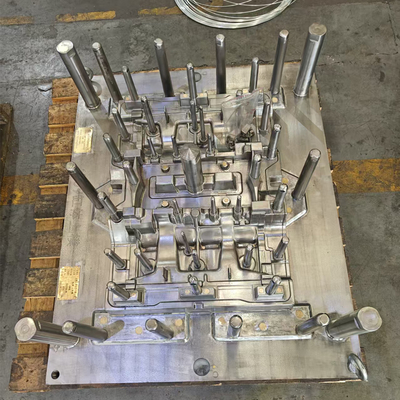

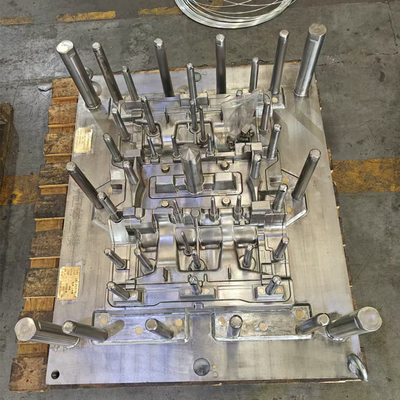

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Custom Sand Casting Moulds for Automotive and Hardware

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Sand Molded Casting | Application | Hardware, Car |

|---|---|---|---|

| Demoulding | Automatic | Surface Treatment | Heat Treatment |

| Customized | Yes | Average Wall Thickness | >4mm |

| Highlight | custom sand casting molds automotive,sand casting molds for hardware,durable sand casting moulds |

||

Metal castings are created via the sand casting method, which uses disposable sand molds. This versatile process allows for the creation of intricate shapes and can accommodate metal components ranging from a few ounces to several tons. Sand molds enable production of castings with complex exterior details, inner cores, and various shapes, working with nearly any metal alloy.

| No. | Item | Specification |

|---|---|---|

| 1 | Brand | Liushi |

| 2 | Mould | Sand casting Mould |

| 3 | Process | Sand casting |

| 4 | Certificate | ISO 9001:2008 |

| 5 | Product Material | Sand & Resin |

| 6 | Casting Material | Aluminum Alloy |

| 7 | Treatment | Sand blasting, powder coating, plating or other custom requirements |

| 8 | Drawing and Software | Customer provides 3D drawing of final product or mould |

| 9 | Package | Wooden case package |

| 10 | Delivery period | 1-2 weeks for samples, 3-4 weeks for mass production |

| 11 | Place of Origin | Luoyang, China |

Glass ribs, glass clamps, vehicle parts, LED housing, support brackets, machine parts, motorcycle spare parts, agricultural machinery parts, engineering machinery parts, engine components, aluminum generator spare parts, engine bushings, automobile radiator accessories, power generation components, engine blocks, regulator housing, clapboards, crane spare parts, general mechanical parts, medical device components, scaffold spare parts, national defense components, construction spare parts, mining mechanical parts, material handling spare parts, LED covers, LED heatsinks, water pump components, light cases, industrial equipment components, baffle plates, machine bases, automobile suspension parts, motor pedestals, truck parts, and more.

- Incoming quality control (IQC) - Raw material inspection upon arrival

- Pre-production inspection of all details

- In-process quality control (IPQC) - Full inspection during mass production

- Final quality control (FQC) - Comprehensive inspection of finished goods

Products are securely packed in wooden cases to prevent damage during transit. Custom packaging solutions available upon request. We handle all logistics from initial consultation to delivery at your chosen port worldwide. Suitable for seaway transportation with customizable packing methods.

- Leading foundry mould manufacturer with extensive machining capabilities

- Team of 3 senior casting mould craftsmen and 36 professional designers

- Precision CNC machining for uniform thickness and high-quality mould cavities

- ZL104 Aluminium construction for high-strength moulds

- Advanced cooling systems with copper tube and water spray technology

- TEF10N coating for reduced friction and superior surface finish

- Stainless steel screws for easy maintenance

- Thick wrought aluminium plates for high-strength cavities

- Automatic moulds with take-out devices for complex designs

- Pattern sample production for quality verification

- Swiss-made Hexagon coordinate measuring instrument for precision testing

Please provide your product drawing, quantity, weight, and material specifications.

Yes, we can reverse engineer drawings from your sample.

Samples: 15-30 days after mold production begins. Production: 35-40 days (varies by product).

Tooling: 50% advance, balance after sample approval. Orders: 30% deposit, 70% against B/L copy.

PDF, IGS, DWG, STEP, JPG, PNG, MAX.

Powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip galvanizing, electrophoresis, chrome plating.

Normally packed according to customer requirements, with wooden case as standard.