-

Aluminum Alloy Casting

-

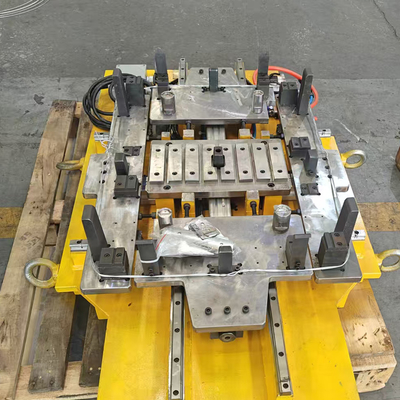

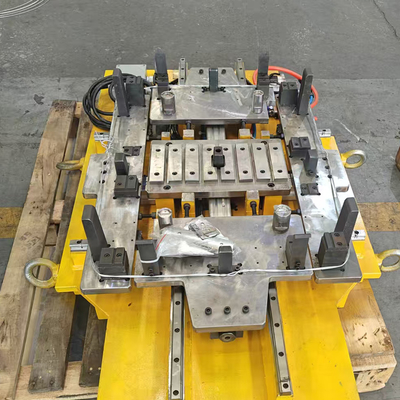

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Automotive Sand Casting Moulds for Aluminum Alloy Components

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Sand Molded Casting | Application | Hardware, Car |

|---|---|---|---|

| Demoulding | Automatic | Surface Treatment | Heat Treatment |

| Customized | Yes | Average Wall Thickness | >4mm |

| Highlight | aluminum alloy sand casting moulds,automotive sand casting molds,sand casting moulds for components |

||

| Attribute | Value |

|---|---|

| Product Name | Sand Molded Casting |

| Application | Hardware, Car |

| Demoulding | Automatic |

| Surface Treatment | Heat Treatment |

| Customized | Yes |

| Average Wall Thickness | >4mm |

High-density production mould systems enabling simultaneous casting of multiple identical components. Modular architecture supports rapid configuration changes and scalable output without compromising individual cavity precision.

| No. | Item | Specification |

|---|---|---|

| 1 | Brand | Liushi |

| 2 | Mould | Sand casting Mould |

| 3 | Process | Sand casting |

| 4 | Certificate | ISO 9001:2008 |

| 5 | Product Material | Sand & Resin |

| 6 | Casting Material | Aluminum Alloy |

| 7 | Treatment | Sand blasting, powder coating, plating or other you want |

| 8 | Drawing and Software | Customer provide 3D drawing of final product or 3D drawing of mould |

| 9 | Package | Wooden case package |

| 10 | Delivery period | 1-2 weeks for samples, 3-4 weeks for mass production |

| 11 | Place of Origin | Luoyang, China |

- Cooperated with clients in more than 10 countries and regions worldwide

- Own factory with over 40 senior professional technicians

- Competitive pricing structure

- High precision manufacturing

- Advanced fully equipped facilities

- 6 years of export experience

- Small orders accepted with one-stop service including mould and assembly

Glass Ribs, Glass Clamps, Vehicle Parts, LED housing, Support Bracket, Machine Parts, Motorcycle Spare Parts, Agricultural Machinery Parts, Engineering Machinery Parts, Engine Components, Aluminum Generator Spare Parts, Engine Bushing, Automobile Radiator Accessories, Power Generation Industries Components, Engine Blocks, Regulator Housing, Clapboard, Crane Spare Parts, General Mechanical Parts, Medical Devices Components, Scaffold Spare Parts, National Defense Components, Construction Spare Parts, Mining Mechanical Parts, Material Handling Spare Parts, LED Cover, LED HeatSink, Water Pump Spare Parts, Light Cases, Water Pump Spare Parts Components, General Industrial Equipment Components, Baffle Plate, Machine Bases, Automobile Suspension Spare Parts, Motor Pedestal, Truck Parts, etc.

- Checking the raw material after they reach our factory - Incoming quality control (IQC)

- Checking the details before the production line operated

- Full inspection and routing inspection during mass production - In process quality control (IPQC)

- Checking the goods after they are finished - Final quality control (FQC)

Design to Finished Products: We provide complete die casting products, including 3D flow analysis, high pressure die casting, trimming, hand cleaning, drilling, tapping, machining, vibratory finishing, shot blasting, satin sanding, painting, powdercoating, E coating, anodizing, polishing, plating, coating, bar coding, assembly and packaging.

High Quality Castings: We consistently produce high quality precision aluminum castings and zinc castings with consistent surface finishes. Our extensive experience in die casting ensures products that meet fit, form, function and on-time delivery requirements.

Our products are packed in wooden cases to ensure zero damage. We accommodate specific packaging requirements and arrange timely delivery to your chosen port worldwide. We can customize packing methods according to customer needs, suitable for seaway transportation.