-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

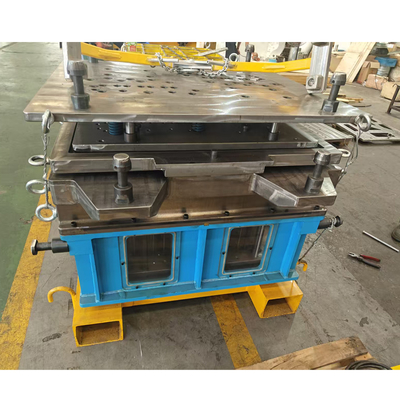

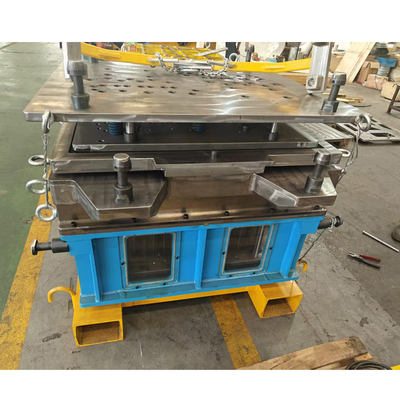

Custom Sand Casting Moulds for Automotive & Hardware

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Sand Molded Casting | Application | Hardware, Car |

|---|---|---|---|

| Demoulding | Automatic | Surface Treatment | Heat Treatment |

| Customized | Yes | Average Wall Thickness | >4mm |

| Highlight | custom sand casting moulds for automotive,sand casting moulds for hardware,durable sand casting moulds |

||

| Attribute | Value |

|---|---|

| Product Name | Sand Molded Casting |

| Application | Hardware, Car |

| Demoulding | Automatic |

| Surface Treatment | Heat Treatment |

| Customized | Yes |

| Average Wall Thickness | >4mm |

Sand casting is a versatile metal forming technique that relies on sand-based molds to shape molten metal. Our ultra-precise sand casting moulds feature micron-level tolerance control for critical dimension replication, incorporating FEA-validated designs and hardened tool steel inserts to maintain ±0.1mm accuracy throughout production runs.

| No. | Item | Specification |

|---|---|---|

| 1 | Brand | Liushi |

| 2 | Mould | Sand casting Mould |

| 3 | Process | Sand casting |

| 4 | Certificate | ISO 9001:2008 |

| 5 | Product Material | Sand & Resin |

| 6 | Casting Material | Aluminum Alloy |

| 7 | Treatment | Sand blasting, powder coating, plating or other custom requirements |

| 8 | Drawing and Software | Customer provides 3D drawing of final product or 3D drawing of mould |

| 9 | Package | Wooden case package |

| 10 | Delivery period | 1-2 weeks for samples, 3-4 weeks for mass production |

| 11 | Place of Origin | Luoyang, China |

- Global client base with cooperation in more than 10 countries and regions

- Own factory with over 40 senior professional technicians

- Competitive pricing structure

- High precision manufacturing capabilities

- Advanced fully equipped facilities

- 6 years of export experience

- Small order acceptance with one-stop service including mould and assembly

Train & railway, automobile & truck, construction machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine, hardware, power equipment and more.

We maintain strict quality control with each casting having a tracking paper and unique ID. Our inspectors take full responsibility for defect identification, ensuring thorough quality checks at every stage.

- Design to Finished Products: Complete die casting solutions including 3D flow analysis, high pressure die casting, finishing, and various surface treatments

- High Quality Castings: Consistent production of precision aluminum and zinc castings with excellent surface finishes

Luoyang Liushi Mould Co., Ltd, established in 2001, is the National Standard Setting Unit for Lost Foam Casting Mould. Located in Luoyang City, we operate from a 9,800 sqm office building and 22,000 sqm workshop, equipped with comprehensive facilities for research, development, design, foundry, machining, assembly, and surface treatment.