-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

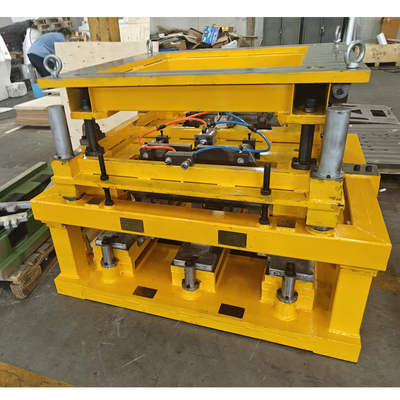

Custom Sand Casting Mould for Iron Parts with Heat Treatment

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Sand Molded Casting | Application | Hardware, Car |

|---|---|---|---|

| Demoulding | Automatic | Surface Treatment | Heat Treatment |

| Customized | Yes | Average Wall Thickness | >4mm |

| Highlight | custom aluminum alloy sand casting mould,automotive parts sand casting mould,sand casting mould with warranty |

||

| Attribute | Value |

|---|---|

| Product Name | Sand Molded Casting |

| Application | Hardware, Car |

| Demoulding | Automatic |

| Surface Treatment | Heat Treatment |

| Customized | Yes |

| Average Wall Thickness | >4mm |

Metal castings are created via the sand casting method, which uses disposable sand molds. Sand can be used to create intricate shapes, making casting an efficient manufacturing procedure. Success in foundry operations using molten metal requires careful consideration of numerous elements.

Metal components of any size, from a few ounces to several tons, can be made by casting. Castings with intricate exterior details, inner cores, and various shapes can be produced using sand molds. Almost any metal alloy can be sand cast. Melted metal is poured into hollows created in moistened sand, which are then allowed to cool.

| No. | Item | Specification |

|---|---|---|

| 1 | Brand | Liushi |

| 2 | Mould | Sand casting Mould |

| 3 | Process | Sand casting |

| 4 | Certificate | ISO 9001:2008 |

| 5 | Product Material | Sand & Resin |

| 6 | Casting Material | Aluminum Alloy |

| 7 | Treatment | Sand blasting, powder coating, plating or other custom treatments |

| 8 | Drawing and Software | Customer provides 3D drawing of final product or 3D drawing of mould |

| 9 | Package | Wooden case package |

| 10 | Delivery period | 1-2 weeks for samples, 3-4 weeks for mass production |

| 11 | Place of Origin | Luoyang China |

- Global client base with cooperation in more than 10 countries and regions

- Own factory with over 40 senior professional technicians

- Competitive pricing structure

- High precision manufacturing

- Advanced fully equipped facilities

- 6 years of export experience

- Small orders accepted with one-stop service including mould and assembly

Luoyang Liushi Mould Co., Ltd was established in 2001 and is the National Standard Setting Unit for Lost Foam Casting Mould. Located in Luoyang City, we have a 9,800 sqm office building and 22,000 sqm workshop, equipped with comprehensive facilities for research, development, design, foundry, machining, assembly, and surface treatment. We serve as Luoyang's municipal R&D center and technology center.