-

Aluminium Die Casting Mould

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminum Alloy Casting

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

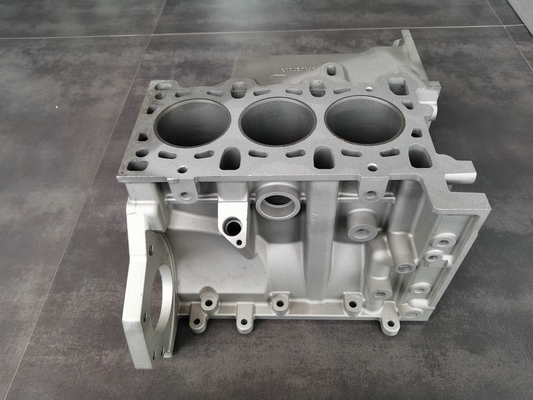

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Aluminium Low Pressure Gravity Casting Mould Pro/E Design Process

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface Treatment | Polishing | Cavity Number | Multi-Cavity |

|---|---|---|---|

| Process | Low Pressure/ Gravity Casting | Packaging | Wooden Case |

| Design Software | UG, Pro/E, AutoCAD | Mould Standard | Custom Made |

| Material | Aluminium | Mould Life | 100000 Shots |

| High Light | Aluminium Gravity Casting Mould,Low Pressure Gravity Casting Mould,Polishing Gravity Casting Mould |

||

Aluminium Low Pressure/ Gravity Casting Mould Pro/E Design Process![]()

![]()

Product Description:

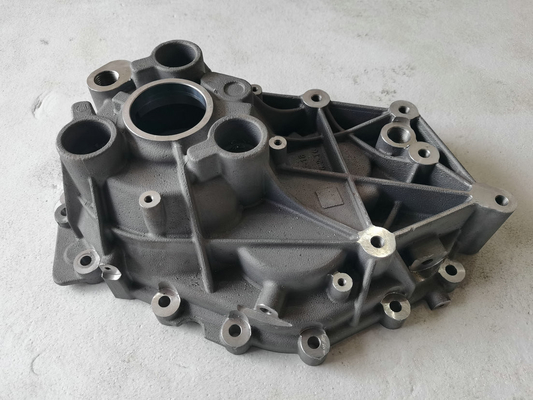

Aluminium Die Casting Mould is a kind of metal casting mould which is mainly used for cylinder head mould. It is made of aluminium material and its surface can be treated with polishing process. Also, the mould has a long life up to 100000 shots. With the help of advanced design software like UG, Pro/E, AutoCAD, the lead time for Aluminium Die Casting Mould is 35-40 days. This aluminium casting mould is an ideal solution for the mass production of cylinder head mould.

Features:

- Product Name: Aluminium Die Casting Mould

- Mould Type: Casting Mould

- Mould Life: 100000 Shots

- Material: Aluminium

- Lead Time: 35-40 Days

- Process: Die Casting

- Speciality: Metal Casting Mould, Lost Foam Mould

Technical Parameters:

| Technical Parameter | Description |

|---|---|

| Mould Life | 100000 Shots |

| Mould Testing | In-House |

| Process | Die Casting |

| Mould Type | Casting Mould |

| Surface Treatment | Polishing |

| Material | Aluminium |

| Design Software | UG, Pro/E, AutoCAD |

| Packaging | Wooden Case |

| Cavity Number | Multi-Cavity |

| Mould Standard | HASCO, DME |

Applications:

Liushi aluminium die casting moulds are designed using professional software such as UG, Pro/E and AutoCAD, and are manufactured in Luoyang with the highest quality standards. The moulds are produced for 100000 shots, and are made with the most advanced die casting process. We use standard mould components provided by HASCO and DME to ensure the highest reliability and durability of the mould. Our Liushi die casting moulds are the perfect choice for many applications, as they provide superior strength and long-lasting reliable performance. With our aluminium casting mould design, you can achieve the highest quality and accuracy for your casting products. We guarantee our moulds are perfect for any casting project.

Customization:

Customized Aluminium Die Casting Mould by Liushi in Luoyang

We know that the quality of your products depends on the accuracy and performance of your moulds. That's why Liushi in Luoyang offers customized aluminium die casting moulds of the highest quality, using the latest design software such as UG, Pro/E and AutoCAD. We use the finest aluminium materials and multi-cavity moulds to ensure that our products meet your exact needs.

Support and Services:

- Provide guidance for the design and production of moulds

- Provide guidance for the selection of materials

- Provide technical advice for the determination of moulding parameters and die casting parameters

- Provide technical support and services for the production and performance testing of the mould

- Provide technical support and services for the improvement and optimization of the mould

- Provide regular maintenance and repair services for the mould

Packing and Shipping:

Aluminium Die Casting Moulds are packed in either wooden boxes or other suitable packaging material, depending on their size, shape, and weight. Shipping is done via reliable carriers such as UPS, FedEx, DHL, or others, to ensure safe and timely delivery.

FAQ:

A1: Aluminium Die Casting Mould is a mould used in the die casting process to produce high precision aluminium parts. It is produced by Liushi, a brand from Luoyang.

A2: Aluminium die casting mould has the advantages of good surface finish, dimensional accuracy, high strength, and excellent wear resistance. It is also cost-effective and have a long-service life.

A3: Aluminium die casting mould is widely used in many industries, including automotive, electrical, aerospace, and construction industries. It is also used for making complex shapes and sizes of components.

A4: Liushi aluminium die casting mould is known for its high precision, durability and reliability. It is made from high-grade materials and designed to meet the requirements of various industries.

A5: The maximum size of aluminium die casting mould from Liushi is 5 meters in length, 2 meters in width, and 1 meter in height.