-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

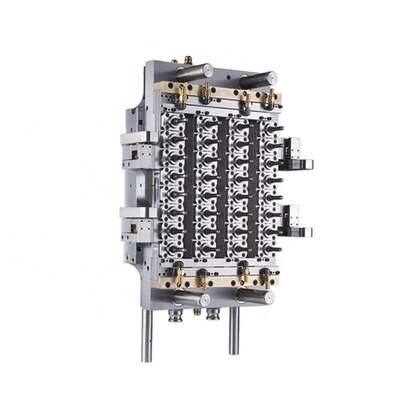

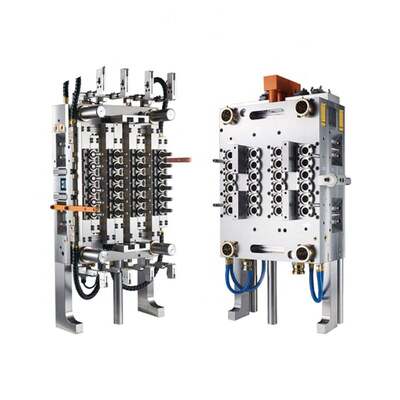

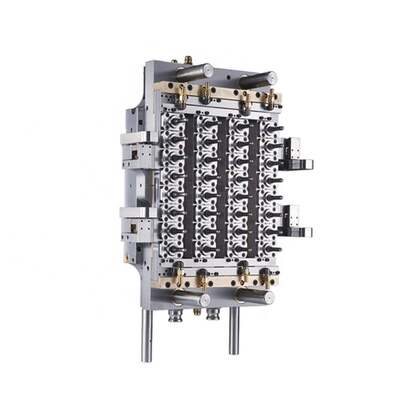

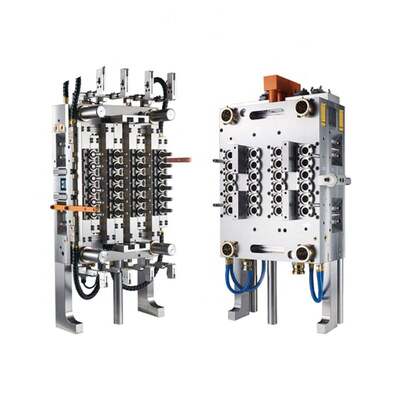

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Factory Custom PET Plastic Preform Mold Stainless Steel Injection Mould Multi-Cavity Mold

| Product Name | Multi Cavity Mold | Customized | Yes |

|---|---|---|---|

| Demoulding | Automatic | Using Hardness | >HRC45 |

| Mould Life | 50,000-100,000 Shots | Mold Material | EPS |

| Surface Treatment | Heat Treatment | Average Wall Thickness | >3mm |

| Product Range | Auto Parts,light,Industrial,furniture | Type | Lost Foam Casting |

| Highlight | PET plastic preform injection mold,stainless steel multi-cavity mold,custom preform mold with warranty |

||

Factory Custom PET Plastic Preform Mold Stainless Steel Injection Mould Multi-Cavity Mold

What is a multi cavity mold? Production leap: Directly increase your production efficiency by several times, meet the cost dilution requirements for large-scale delivery: Although the mold investment is slightly higher, when allocated to each product, your individual part production cost (labor, energy consumption, machine hours) will significantly decrease, and the profit margin will be larger. Consistent quality: All products are formed at the same time and under the same process, ensuring the stability of the size and quality of the entire batch of products.

Mold Proudct Range

Transportation, Agricultural machinery equipment, Construction machinery, Water conservancy facilities, Space flight and aviation, Chemical machinery, Sea carriage and so on.

Mold Features

- Engineering With Accuracy and Stability Dimensional

- Easily Assembled and Disassembled;

- Low maintenance

- Longer life

- Fine finish

- High strength

- Rugged design

- Durable nature

Product Description

|

Multi-Cavity Mold

|

||

|

Customizd

|

||

|

Hot&Cold Runner

|

||

|

UG,CAD/CAM,PROE

|

||

|

Corrosion Resistance, Polishing Process, Wire Drawing Treatment

|

||

|

Nitrogen Treatment

|

||

|

CNC,High-speed engraving,Digital controller lathes,etc

|

||

|

Ten Million Cycles

|

||

|

ABS,PPR,PC,PP,PVC,POM,PMMA,PS,PE,PET,PA,PBT,PEI etc.

|

||

|

LKM or as required

|

||

|

HASCO, DME, Musumi or as required

|

Manufacture Process

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

![]()

Quality Control

We strictly control production process by using computer to monitor 24/7, in order to enhance and stable the production quality. VCU has its own highly qualified QC team equipped with all necessary and state-of-the-art testing equipment to be able to perform 100% inspection in order to ensure the best quality products that will be delivered to all of our customers.

Applicable scenarios:

Suitable for plastic parts with high demand and long lifecycle, such as bottle caps, electronic connectors, daily consumer goods, toy parts, etc.

Our Advantages

-

Precision temperature control throughout casting process

-

Reduced cycle times through efficient heat extraction

-

Minimized thermal stresses in mold components

-

Consistent microstructure in cast components

-

Adaptable to various aluminum alloys

Packaging & Shipping

Our products are all packed in wooden cases to ensure zero damage. If customers have specific requirements for the packaging, we will gladly accommodate. The products will be sent to you on time and we will arrange everything from the initial consultation to the delivery of your chosen port anywhere the world. We can also customize the packing method according to customers' needs. Suitable for seaway transportation.

![]()

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is National Standard Setting Unit for Lost Foam Casting Mould. The company is located in the Millennium Emperor, peony flower city of Luoyang City. We have 9800 office building, and 22000 workshop, which is well equipped with research, development, design, foundry, machining, assembly, surface treatment and other equipment. It′s a Luoyang municipal R&D center and technology center.

Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.