-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

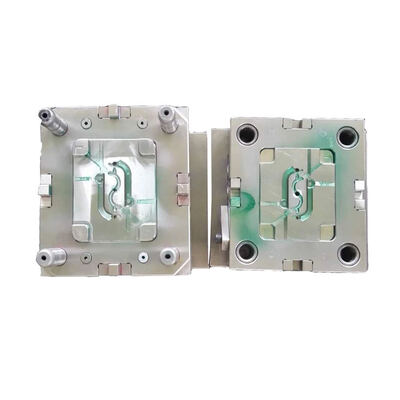

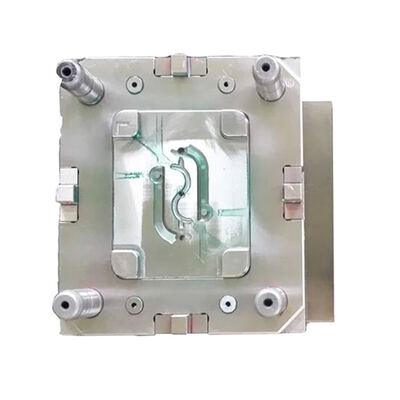

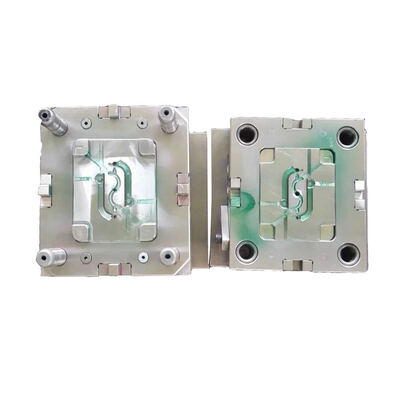

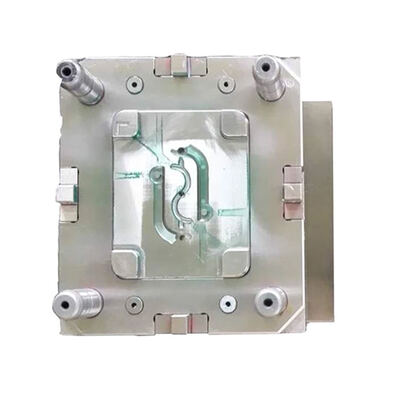

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Plastic Injection Molding Mold Manufacturer Factory Price 2 Cavity 4 Cavity 8 Cavity Hot Runner Injection Mold

| Product Name | Multi Cavity Mold | Customized | Yes |

|---|---|---|---|

| Demoulding | Automatic | Using Hardness | >HRC45 |

| Mould Life | 50,000-100,000 Shots | Mold Material | EPS |

| Surface Treatment | Heat Treatment | Average Wall Thickness | >3mm |

| Product Range | Auto Parts,light,Industrial,furniture | Type | Lost Foam Casting |

| Highlight | Plastic injection molding mold with warranty,Multi cavity hot runner injection mold,2 cavity plastic injection mold |

||

Plastic Injection Molding Mold Manufacturer Factory Price 2 Cavity 4 Cavity 8 Cavity Hot Runner Injection Mold

For us mold manufacturers, multi cavity molds are the ultimate intersection of efficiency, precision, and cost. It tests our systematic engineering capabilities - from precise hot runner selection, scientific runner design, balanced cooling layout, to selecting the most suitable steel and heat treatment processes. Successfully delivering a stable and efficient set of multi cavity molds to our customers not only provides a 'tool', but also builds long-term market competitiveness for them.

If you have specific products, we can discuss together the possibility, potential challenges, and most cost-effective solution for achieving multi cavity design.

Mold Proudct Range

Transportation, Agricultural machinery equipment, Construction machinery, Water conservancy facilities, Space flight and aviation, Chemical machinery, Sea carriage and so on.

Mold Features

- Engineering With Accuracy and Stability Dimensional

- Easily Assembled and Disassembled;

- Low maintenance

- Longer life

- Fine finish

- High strength

- Rugged design

- Durable nature

Product Description

|

Product Name

|

aluminum mould die casting

|

||

|

Size

|

customized

|

||

|

Color

|

As your requirements

|

||

|

Material

|

Aluminum

|

||

|

Application

|

Auto parts, ,Light fixture, lamp cover, led light housing,heat sink or any other type of die casting parts

|

||

|

Service

|

OEM/ODM

|

||

|

Product's Design

|

Customized as customers' drawings or samples

|

||

Manufacture Process1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Core Challenges and Solutions

- Consistent filling and pressure maintenance: Even if the flow channel is balanced, subtle differences in each cavity (polishing, exhaust, cooling) may lead to inconsistent filling. We use mold flow analysis software (such as Moldflow) for simulation, problem prediction, and optimization before manufacturing.

- Cooling uniformity: The cooling design of multi cavity molds is like "urban planning". It is necessary to ensure that each cavity, especially the core (moving mold) side, receives an equal amount of cooling. Parallel cooling circuits and imitation waterways are often used to avoid insufficient end cooling caused by series connection.

- The rigidity and lifespan of molds: More cavities mean larger templates and more complex internal structures. We use pre hardened mold steel or H13 type hot work steel, and perform special heat treatment (nitriding) at critical locations such as channel intersections and small cores to resist long-term alternating stress and prevent premature cracking or wear.

- Fine management of exhaust: The exhaust of each cavity must be independent and sufficient. We will set carefully calculated exhaust grooves at the parting surface, top pin, and insert, with a depth usually accurate to 0.01-0.03mm, to ensure that gas is discharged and plastic does not overflow

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is National Standard Setting Unit for Lost Foam Casting Mould. The company is located in the Millennium Emperor, peony flower city of Luoyang City. We have 9800 office building, and 22000 workshop, which is well equipped with research, development, design, foundry, machining, assembly, surface treatment and other equipment. It′s a Luoyang municipal R&D center and technology center.

![]()

Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.