-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

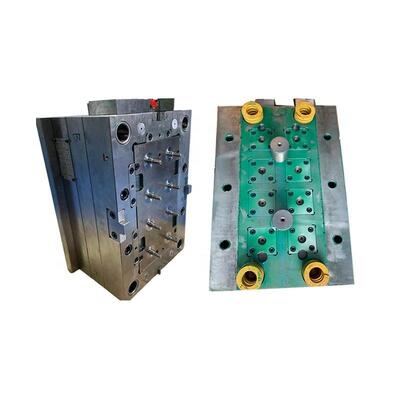

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

OEM Multi Cavities Plastic Injection Mold Making Manufacturer Factory

| Product Name | Multi Cavity Mold | Customized | Yes |

|---|---|---|---|

| Demoulding | Automatic | Using Hardness | >HRC45 |

| Mould Life | 50,000-100,000 Shots | Mold Material | EPS |

| Surface Treatment | Heat Treatment | Average Wall Thickness | >3mm |

| Product Range | Auto Parts, ,light,Industrial,furniture | Type | Lost Foam Casting |

| Highlight | OEM plastic injection mold manufacturer,multi cavity plastic injection mold,custom plastic injection mold factory |

||

OEM Multi Cavities Plastic Injection Mold Making Manufacturer Factory

a multi cavity mold is a mold system that manufactures multiple identical products simultaneously within a single mold.

Core metaphor: Like a mold for baking a cake. A single cavity mold can only bake one cake at a time. A "multi cavity" cake mold (such as a six cup mold) can bake six identical cakes at once.

Working principle: In processes such as injection molding, die casting, or stamping, molten plastic or metal is injected or filled into multiple identical cavities simultaneously through a distribution channel system inside the mold. After one molding cycle, multiple identical parts can be obtained.

Multi Cavity Mold Proudct Range

Transportation, Agricultural machinery equipment, Construction machinery, Water conservancy facilities, Space flight and aviation, Chemical machinery, Sea carriage and so on.

Multi Cavity Mold Features

1.Extremely high production efficiency: This is the primary objective. For example, the output completed by a 16 cavity mold in one production cycle is equivalent to 16 runs of a single cavity mold. This can significantly reduce the production cycle time and labor costs of individual parts, and is the core tool for achieving large-scale production.

2. Reduce single piece cost: Although the initial manufacturing cost of multi cavity molds is higher (with more complex designs, more materials, and extremely high processing accuracy requirements), when the production reaches a certain scale, the mold cost, machine hours, and energy consumption allocated to each part will significantly decrease, thereby obtaining highly competitive single piece prices.

3.Excellent parts consistency: All cavities are filled and cooled under the same process parameters (pressure, temperature) at the same time, theoretically ensuring that all parts produced in the same batch have highly consistent quality and size, which is crucial for precision parts.

4.Save equipment resources: By using one injection molding machine or die-casting machine with multiple cavity molds, it is possible to achieve the output of multiple machines producing simultaneously, thereby saving factory space and machine investment.

Production Specification

|

Product Name

|

Aluminum mould die casting

|

||

|

Size

|

Customized

|

||

|

Color

|

As your requirements

|

||

|

Material

|

Aluminum

|

||

|

Application

|

Auto parts, ,Light fixture, lamp cover, led light housing,heat sink or any other type of die casting parts

|

||

|

Service

|

OEM/ODM

|

||

|

Product's Design

|

Customized as customers' drawings or samples

|

||

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

What We Do

1.We make Export Mold / Mould;

2.We do Injection Molding Service;

3.Assembly and Packing Service

After-sales Service

Experienced engineers will provide all-round technical solutions to any problems occurred in customers' mould operation

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is National Standard Setting Unit for Lost Foam Casting Mould. The company is located in the Millennium Emperor, peony flower city of Luoyang City. We have 9800 office building, and 22000 workshop, which is well equipped with research, development, design, foundry, machining, assembly, surface treatment and other equipment. It′s a Luoyang municipal R&D center and technology center.

![]()

Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.