-

Aluminum Alloy Casting

-

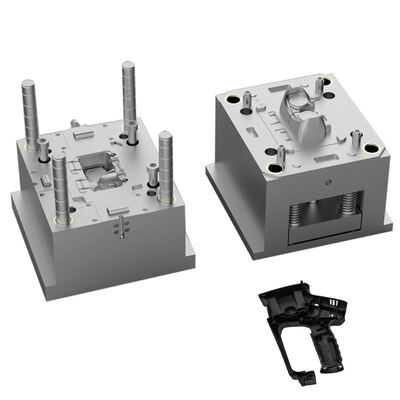

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Customized Single Cavity Manufacturing Auto Parts Plastic Injection Mold

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Plastic Injection Mold | Mould Life | >1,000,000 Shots |

|---|---|---|---|

| Surface Treatment | Heat Treatment | Product Range | Automotive Parts Mold |

| Average Wall Thickness | >3mm | Function | Anti Corrosion |

| Highlight | customized single cavity auto parts mold,plastic injection mold for auto parts,auto parts manufacturing injection mold |

||

Customized Single Cavity Manufacturing Auto Parts Plastic Injection Mold

We offer innovative and efficiency-focused Auto Parts Mould solutions designed to thrive in the competitive landscape of automotive manufacturing. Our approach combines cutting-edge manufacturing techniques with a deep understanding of production economics to deliver moulds that maximize output, minimize operational costs, and accelerate time-to-market for new vehicle programs. We focus on creating intelligent tooling that enhances your overall manufacturing agility and responsiveness to market demands.

Features

-

Rapid Cycle Time Optimization: The mould design is fundamentally centered on achieving the fastest possible cycle time through balanced filling, efficient cooling, and streamlined ejection, directly boosting your production capacity.

-

Family Mould & Multi-Cavity Expertise: We expertly design family moulds for related parts or high-cavitation moulds for small components, maximizing each shot's yield and improving per-part cost efficiency.

-

Easy Maintenance & Serviceability: Designed with accessibility in mind, featuring standardized components, easily replaceable wear parts, and clear access to cooling and ejection systems to reduce mean time to repair (MTTR).

-

Lightweighting & Material Efficiency: Our designs often incorporate part and runner system optimization to minimize plastic usage without compromising strength, supporting automotive lightweighting initiatives and reducing material costs.

Specification

|

Product Name

|

Auto Parts Mould

|

||

|

Size

|

Customized

|

||

|

Color

|

As your requirements

|

||

|

Material

|

Aluminum, Metal, As your requirements

|

||

|

Application

|

Auto parts, Light fixture, lamp cover, led light housing, heat sink or any other type of die casting parts

|

||

|

Service

|

OEM/ODM

|

||

|

Product's Design

|

Customized as customers' drawings or samples

|

||

Our Factory

![]()

![]()

![]()

![]()

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

![]()

Application

These high-efficiency moulds are particularly valuable for the mass production of high-volume, cost-sensitive automotive parts. This includes clusters of small components like clips, grommets, connectors, and fasteners; interior trim pieces; ductwork for HVAC systems; and various housings and covers. They are also excellent for producing components for electric vehicles, where efficiency and precision in both part and production process are critical.

Our Advantages

1. We are the one of the biggest lost foam mould manufacturer in China, we focus on high challenge lost foam mould and we have large gantry machining centers,30 sets imported high speed machining center,more than 40 sets general machine tool equipment;

2. We have 36 senior mould designers, to ensure reasonable / safety / high efficiency mould design and ensure the fast mould delivery and rational mould structure, make the process more safer and the production efficiency more higher;

3. We using numerical control machine tool to manufacture the mould cavities, to ensure a even thickness ;

4. We using ZL104 Aluminium to casting the mould, to manufacture a high strength mould;

5. For the big mould, we using Ø22*1 copper tube as cooling pipe, with water spray system, to get a nice cooling effect;

6. We Have (TEF10N) coating on the mould surface, it can reduce the friction, anti water/static electricity/acid-base/high-temperature, with this we can ensure the pattern has smooth surface without distrotion, and easy to demould;

7. All the screws we using stainless steel screw, easy to disassemble during maintenance;

8. For the big mould chest, we using 18-20mm thick wrought aluminium plate, to offer high strenght cavity ;

9. For the complex mould which is difficult to demould, we can manufacture the automaitc mould with take out device ;

10. We produce the pattern sample to customer after finish the mould, when the pattern was qualified, then we do exceptance job for the mould ;

11. We have the Hexagon coordinate measuring instrument imported from the Switzerland to have a test make sure our mould qualified.

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is National Standard Setting Unit for Lost Foam Casting Mould. The company is located in the Millennium Emperor, peony flower city of Luoyang City. We have 9800 office building, and 22000 workshop, which is well equipped with research, development, design, foundry, machining, assembly, surface treatment and other equipment. It′s a Luoyang municipal R&D center and technology center.

![]()

Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.

Why Choose Us

- Focus on Your Production KPIs: We align our design objectives with your key performance indicators, whether it's cycle time reduction, scrap rate minimization, or uptime maximization, ensuring our mould delivers tangible business value.

- Prototyping & Pilot Run Support: We offer rapid prototyping services and manage comprehensive pilot production runs, allowing for design validation and process refinement before committing to full-scale production tooling.

- Adaptability to Change: Our modular design philosophies allow for future modifications or cavity additions with relative ease, protecting your investment as part designs evolve or production volumes scale.

- Cost-Transparent Quoting: We provide detailed, breakdown quotations that clearly outline all costs, with no hidden fees, enabling accurate budgeting and clear financial planning for your project.