-

Aluminum Alloy Casting

-

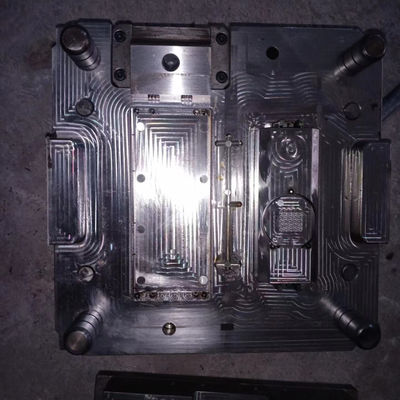

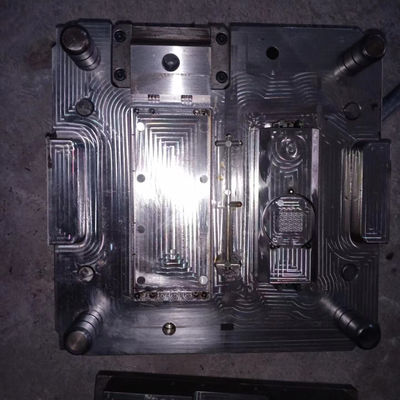

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Aluminum Alloy Die Casting Molds Aluminum Products Custom Made

| Product Name | Aluminium Die Casting Mould | Customized | Yes |

|---|---|---|---|

| Demoulding | Automatic | Casting Mold | Design, Fabrication, Test, Modification & Maintenance |

| Mould Life | 500,000-1,000,000 Shots | Process | Casting +Machining(If Need)+Surface Treatment |

| Surface Treatment | Shot Blast | Average Wall Thickness | >3mm |

| Highlight | Aluminum Alloy Die Casting Molds,Aluminum Products Die Casting Molds,Custom aluminium die casting mould |

||

Aluminum Alloy Die Casting Molds Aluminum Products Custom-made

Our Products

Aluminium Die Casting Mould Parameters

| Material Capability | Aluminum, Zinc, Brass, Iron, Carbon steel, Stainless steel, etc. |

| Surface Treatment | Shot blast, beat blast, powder coating, painting, zinc plating, hot dip galvanized, electrophoreses etc. |

| Product Weight | 0.01KG-50000KG |

| Casting Tolerance | CT3-CT9 |

| Trade Terms | FOB |

| Packing | single polybag, bubble bags, wooden case, carton box etc. |

| Delivery terms | 15-45 days for bulk |

Our Advantages

Manufacture Proces![]()

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Packing & Shipping

![]()

About Us

While leading the Chinese brand, Luoyang Liushi mould develop the international market positively, we export a large number of molds to the United States, India, Taiwan and other countries. We have become an international first-class lost foam mould supplier and we have manufactured mould for Germany's machine Teubert and American molding machine Vulcan.

![]()

Our engineers have developed specialized cooling systems and gate designs that ensure complete cavity filling without defects. The moulds maintain exceptional dimensional stability even when producing parts with wall thicknesses below 1mm. Ideal for electronics housings, automotive lightweight components, and consumer products, these precision moulds enable you to push the boundaries of aluminium die casting while maintaining structural integrity in your parts.

.![]()

Ready to Boost Your Production Efficiency? Place Your Order Today!

Upgrade to our high-performance aluminum die casting molds and experience faster cycle times, superior durability, and flawless part quality. With our 24/7 customer support and proven track record, you can order with confidence. Contact us now for a personalized quote and take the first step toward stress-free manufacturing!