-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

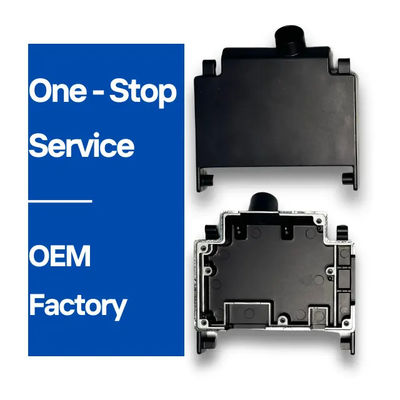

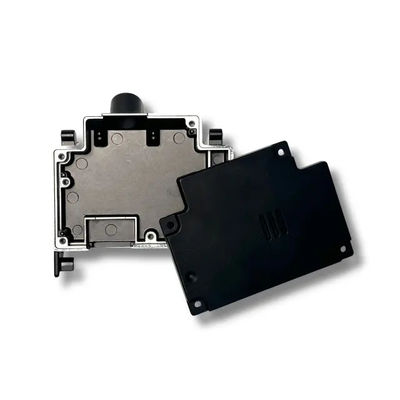

High Strength Aluminum Die Casting Mold Housing Parts Low Pressure Custom Fast Delivery

| Product Name | Aluminium Die Casting Mould | Customized | Yes |

|---|---|---|---|

| Demoulding | Automatic | Mould Life | 500,000-1,000,000 Shots |

| Surface Treatment | Shot Blast | Type | High Quality Non-ferrous Die Cast Components |

| Certificate | ISO9001:2008 | Application | Precision Metal Parts And Components / Computer Peripherals / Consumer Electrical Components / Medical / Industrial Components / Telecommunications / Automotive / Lighting Components / Furniture Components Etc. |

| Highlight | Low Pressure Aluminum Die Casting Mold,Fast Delivery Aluminum Die Casting Mold,Custom aluminum die casting mould |

||

High Strength Aluminum Die Casting Mold & Housing Parts Low Pressure Custom Castings With Fast Delivery

Our Products

Corrosion-Resistant Moulds for Aluminum Die Casting

Featuring special coatings and treatments, our moulds resist aluminum adhesion and corrosion. Maintain superior surface finish and dimensional stability through extended production runs.

Specializes in custom die-casting services using high-strength alloys like aluminum, zinc, and magnesium. Supports various surface treatments (powder coating, polishing) and strict 100% QC inspection with ISO 9001 certification. RoHS compliance ensures environmental safety and market ac cess for buyers

Aluminium Die Casting Mould Parameters

| Material Capability | Aluminum, Zinc, Brass, Iron, Carbon steel, Stainless steel, etc. |

| Surface Treatment | Shot blast, beat blast, powder coating, painting, zinc plating, hot dip galvanized, electrophoreses etc. |

| Product Weight | 0.01KG-50000KG |

| Casting Tolerance | CT3-CT9 |

| Trade Terms | FOB |

| Packing | Single polybag, bubble bags, wooden case, carton box etc. |

| Delivery terms | 15-45 days for bulk |

Manufacture Process

![]()

The research and development center is consist of 36 designers who are expert in 3D design, mold design, CNC programming craftsmen, lost foam casting craftsmen and so on. We provide a full range of design and services for you. We discuss the mould process and confirm the scheme with your engineer together, this can guarantee the mould structure more reasonable more safety and more efficiency. We finish the product model and detection through reserve scan and 3D Coordinate Measuring technology to make sure each customer satisfy their mould.

Our Advantages

Packing & Shipping

we ensure your aluminium die casting mould arrives in perfect condition, ready for immediate production. Our professional packing and shipping process minimizes risks and guarantees on-time delivery worldwide.

![]()

About Us

While leading the Chinese brand, Luoyang Liushi mould develop the international market positively, we export a large number of molds to the United States, India, Taiwan and other countries. We have become an international first-class lost foam mould supplier and we have manufactured mould for Germany's machine Teubert and American molding machine Vulcan.

![]()

Our engineers have developed specialized cooling systems and gate designs that ensure complete cavity filling without defects. The moulds maintain exceptional dimensional stability even when producing parts with wall thicknesses below 1mm. Ideal for electronics housings, automotive lightweight components, and consumer products, these precision moulds enable you to push the boundaries of aluminium die casting while maintaining structural integrity in your parts.

Your Perfect Mold Awaits – Custom-Built for Your Needs!

No more compromises. Whether you need high-speed production, ultra-smooth finishes, or complex geometries, our tailor-made molds deliver. 100% quality guarantee and on-time delivery. Request a sample mold trial now!