3.One-stop service for all kinds of custom machining parts

-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

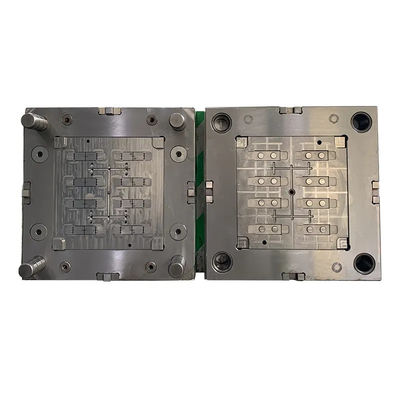

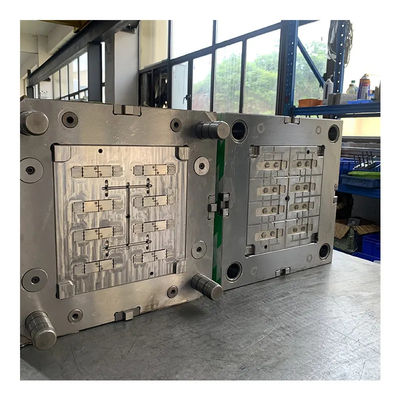

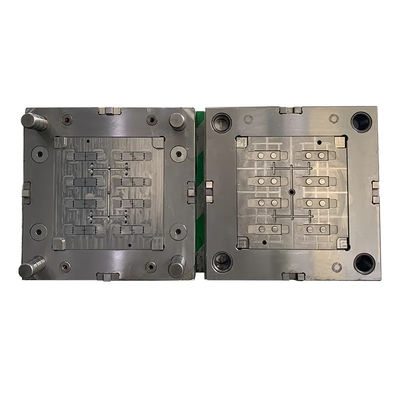

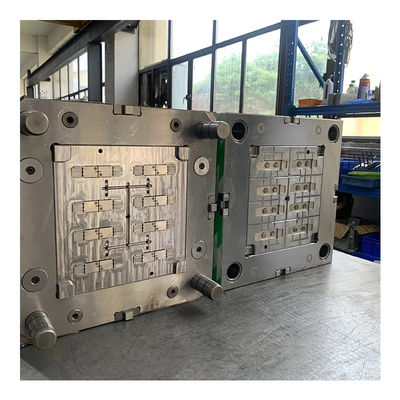

Industrial Grade Durable Aluminum Die Casting Mold For Creating Reliable Industrial Parts And Moulds

| Product Name | Aluminium Die Casting Mould | Customized | Yes |

|---|---|---|---|

| Application | Communication Equipment,Automation Machine, Medical Device | Using Hardness | >HRC45 |

| Mould Life | 500,000-1,000,000 Shots | Process | Casting +Machining(if Need)+Surface Treatment |

| Surface Treatment | Shot Blast | Finish | Anodizing, Nickel Plated, Zinc Plated, Polishing Etc |

| Highlight | Reliable Aluminum Die Casting Mold,Industrial Aluminum Die Casting Mold,Durable Aluminum Die Casting Mold |

||

Industrial-Grade Durable Aluminum Die Casting Mold For Creating Reliable Industrial Parts And Moulds

Our Products

Premium Aluminium Die Casting Moulds for Complex Geometries

Our high-precision aluminium die casting moulds enable flawless production of intricate parts with tight tolerances. Designed for durability and thermal stability, these moulds deliver consistent results across thousands of cycles. Perfect for automotive, electronics & consumer goods industries needing complex aluminum components.

Aluminium Die Casting Mould Features

- Engineering With Accuracy and Stability Dimensional

- Easily Assembled and Disassembled;

- Low maintenance

- Longer life

- Fine finish

- High strength

- Rugged design

- Durable nature

Aluminium Die Casting Mould Parameters

| Material Capability | Aluminum,Zinc,Brass,Iron,Carbon steel, Stainless steel, etc. |

| Surface Treatment | Shot blast, beat blast, powder coating, painting, zinc plating, hot dip galvanized, electrophoreses..etc |

| Product Weight | 0.01KG-50000KG |

| Casting Tolerance | CT3-CT9 |

| Trade Terms | FOB |

| Packing | single polybag, bubble bags,wooden case,carton box..etc |

| Delivery terms | 15-45days for bulk |

Manufacture Process

![]()

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing -

Our Advantages

1. We are the biggest lost foam mould manufacturer in China, we focus on high challenge lost foam mould and we have large gantry machining centers,30 sets imported high speed machining center,more than 40 sets general machine tool equipment;

2. We have 36 senior mould designers, to ensure reasonable / safety / high efficiency mould design and ensure the fast mould delivery and rational mould structure, make the process more safer and the production efficiency more higher;

3. We using numerical control machine tool to manufacture the mould cavities, to ensure a even thickness ;

4. We using ZL104 Aluminium to casting the mould, to manufacture a high strength mould;

5. For the big mould, we using Ø22*1 copper tube as cooling pipe, with water spray system, to get a nice cooling effect.

Packing & Shipping

Dedicated Customer Support

Our customer support team is available to assist you with any questions or concerns regarding packing and shipping. From providing shipping quotes to resolving delivery issues, we’re here to ensure a smooth and hassle-free experience.

![]()

3.One-stop service for all kinds of custom machining parts