-

Aluminum Alloy Casting

-

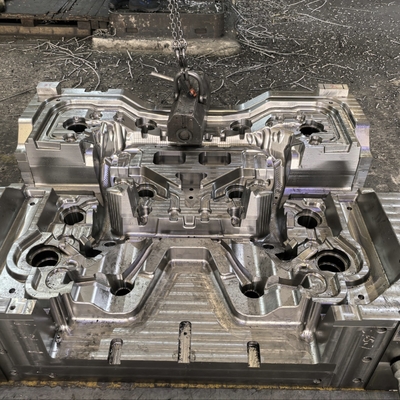

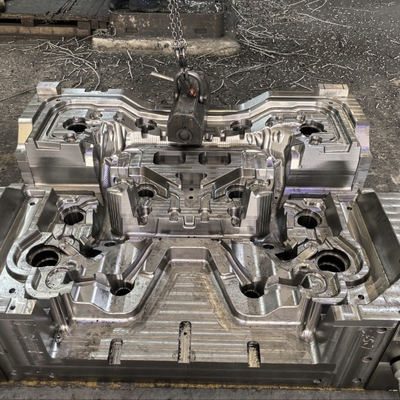

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Cylinder Engine Casting Die Casting Aluminum Alloys Molten Aluminum

| Product Name | Cylinder Engine Casting | Material | Molten Aluminum |

|---|---|---|---|

| Size | OEM | Demoulding | Automatic |

| Mould Life | 50,000-100,000 Shots | Usage | Cylinder |

| Highlight | Cylinder Engine Casting Die,Molten Aluminum Casting Die,Aluminum Alloys Casting Die |

||

Cylinder Engine Casting Die Casting Aluminum Alloys Molten Aluminum

Cylinder engine casting involves manufacturing engine blocks, cylinder heads, and other engine components using specialized casting processes. These components are critical to the performance and efficiency of internal combustion engines in automobiles, motorcycles, and heavy machinery.

Aluminum Alloy Casting Description

|

Product details |

|

|

Material: |

ZL101(ZASI7Mg)/ZL104(ZAISi9Mg) A356. A360.319.AC4C. LM25. ,etc.

|

|

Application: |

Used in Auto parts,Marine,Railway,Machinery,Value,Pump,Art,etc. |

|

Heat treatment: |

T5 .T6 |

|

Casting tolerance: |

Casting CT8,CNC machining CT5 |

|

Certification : |

ISO 9001,ISO 14001,IATF16949,etc. |

|

Surface treatment |

Oxidize, Spray, Spray paint, Electroplating, Various colours according to customer requirements,etc. |

|

Weight range of parts |

0.02kg-500kg |

|

Casting Technology |

Sand casting,Gravity casting ,Die casting,Permanent mould,Precision casting,etc. |

|

Machining process |

CNC lathe -CNC milling -CNC grinding -CNC drilling |

|

QC detection |

X-ray,Spectral content ,Caliper , dial gauge,etc. |

|

Servise: |

OEM and ODM customized |

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery