-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

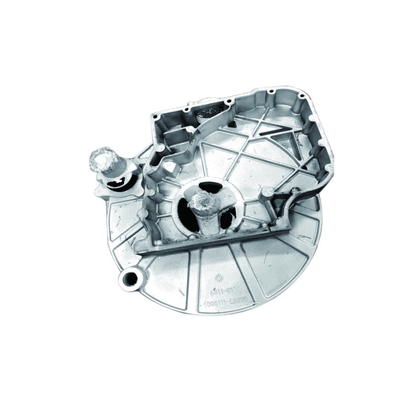

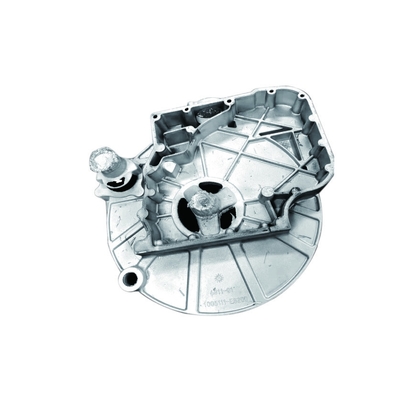

Low Pressure Aluminum Alloy Casting Molding Flywheel Shell

| Product Name | Casting Molding Flywheel Shell | Mold Material | Aluminum Alloy |

|---|---|---|---|

| Surface Treatment | Heat Treatment | Software | AutoCAD, UG, Pro-E, Solidworks |

| Type | Lost Foam Casting | Demoulding | Automatic |

| Average Wall Thickness | >4mm | Mould Life | 50,000-100,000 Shots |

| Product Material | Grey Iron, Ductile Iron | Service | ODM/OEM |

| Highlight | Molding Aluminum Alloy Casting,Flywheel Shell Aluminum Alloy Casting,Low Pressure Aluminum Alloy Casting |

||

Low Pressure Aluminum Alloy Casting Molding Flywheel Shell

The flywheel housing is an automotive component that is usually made of cast iron and is resistant to deformation. It is located between the car engine and transmission, connecting the crankcase, starter and engine oil pan, and has a built-in flywheel assembly. The function of the flywheel housing is to connect the engine and transmission, and has the functions of access to the body, protection and carrier.

The flywheel housing usually consists of a housing, a support plate and bolts. The shell and the support plate are connected by bolts, and the bolts pass through the threaded holes on the support plate and are screwed into the screw holes on the shell. The number and position of the threaded holes on the support plate need to be confirmed according to the assembly requirements of the automobile engine. This design can improve the versatility of the flywheel housing and reduce the use of molds and tooling, thereby reducing production costs and management expenses. At the same time, the structure of the flywheel housing can also reduce the types of parts and save storage and management costs.

Mould Description

1. Drawing: Provide by customer, or design according as the sample.

2. ODM we have the client's idea or draft first,then our experienced engineer will build the best design and manufacturing technology.finally our sales will supply the verified design and solution to our client for confirming.

3. OEM that means Customer design or samples will be very welcome,we will follow client standard to manufacturing this product 100%.

|

Product Name

|

EPS Mould | ||

|

Size

|

Customized

|

||

|

Material

|

Aluminum | ||

|

Application

|

Auto parts, ,Light fixture, lamp cover, led light housing,heat sink or any other type of die casting parts | ||

|

Service

|

OEM/ODM

|

||

|

Product's Design

|

Customized as customers' drawings or samples

|

||

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Our Advantages

1. We are the biggest lost foam mould manufacturer in China, we focus on high challenge lost foam mould and we have large gantry machining centers,30 sets imported high speed machining center,more than 40 sets general machine tool equipment;

2. We have 36 senior mould designers, to ensure reasonable / safety / high efficiency mould design and ensure the fast mould delivery and rational mould structure, make the process more safer and the production efficiency more higher;

3. We using numerical control machine tool to manufacture the mould cavities, to ensure a even thickness ;

4. We using ZL104 Aluminium to casting the mould, to manufacture a high strength mould;

5. For the big mould, we using Ø22*1 copper tube as cooling pipe, with water spray system, to get a nice cooling effect;

6. We Have (TEF10N) coating on the mould surface, it can reduce the friction, anti water/static electricity/acid-base/high-temperature, with this we can ensure the pattern has smooth surface without distrotion, and easy to demould;

7. All the screws we using stainless steel screw, easy to disassemble during maintenance;

8. For the big mould chest, we using 18-20mm thick wrought aluminium plate, to offer high strenght cavity ;

9. For the complex mould which is difficult to demould, we can manufacture the automaitc mould with take out device ;

10. We produce the pattern sample to customer after finish the mould, when the pattern was qualified, then we do exceptance job for the mould ;

11. We have the Hexagon coordinate measuring instrument imported from the Switzerland to have a test make sure our mould qualified.