-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

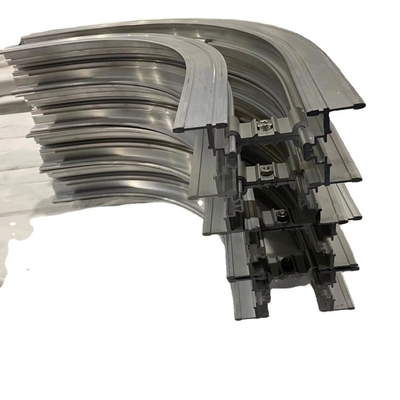

Low Lpdc Pressure Die Casting Mould For Automobile Parts

| Product Name | Low Pressure Die Casting Mould | Product Material | ZL104 Material |

|---|---|---|---|

| Surface Treatment | Heat Treatment | Average Wall Thickness | >3mm |

| Product Range | Automobile Parts | Mould Life | 500,000-1,000,000 Shots |

| Highlight | lpdc pressure die casting mould,automobile parts pressure die casting mould,automobile parts lpdc mold |

||

Low Pressure Die Casting Mould For Automobile Parts

A low-pressure die-casting mold is used in the low-pressure die-casting process, which is a method of manufacturing metal parts with intricate details and complex shapes. This process is commonly used for producing components such as automotive parts, aerospace components, and industrial machinery parts.

| Product Type | Casting Mould |

| Our Services | CNC Machining, stamping (we focus on stamping production)Die casting, Surface Treatment, Stamping Mold-making, etc |

| Application | Industrial, automobile, electronics, electric power, lighting, facility Machinery equipment, construction, etc. |

| Material | Aluminum, Brass, Stainless Steel, Copper, |

| Surface Treatment | Anodizing, Sandblasting, Painting, Powder coating, Plating, Silk Printing, Brushing,Polishing, Laser Engraving. |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Service Project | We can provide production design, massive production, technical service, in-site stamping molding making service. |

| Testing Machine | Video Measuring system, Microscope, Digital Force Gauge, caliper, projector, roughness tester, Salt- spray machine, Stereomicroscope and so on |

| Packing | Foam, Carton, Wooden boxes, or as per the customer’s requirements |

| Payment Terms | T/T |

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is National Standard Setting Unit for Lost Foam Casting Mould. The company is located in the Millennium Emperor, peony flower city of Luoyang City. We have 9800 office building, and 22000 workshop, which is well equipped with research, development, design, foundry, machining, assembly, surface treatment and other equipment. It′s a Luoyang municipal R&D center and technology center.

Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.