-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

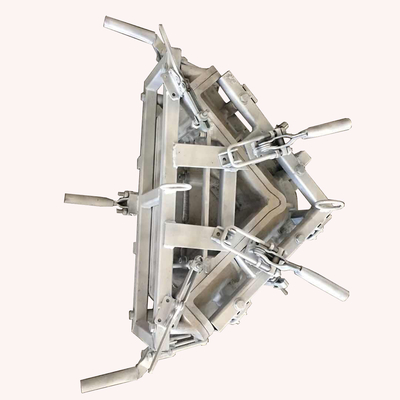

Auto Parts Aluminium Die Casting Mould Low Pressure

| Product Name | Auto Parts Aluminium Die Casting Mould | Using Hardness | >HRC45 |

|---|---|---|---|

| Mould Life | 500,000-1,000,000 Shots | Metal Color | Black Metal |

| Tolerance | 0.03mm | Average Wall Thickness | >3mm |

| Highlight | auto parts aluminium die casting mould,aluminium die casting mould low pressure,auto parts aluminum die casting mold |

||

Pdc Hpdc Aluminium Die Casting Mould Tooling Low Pressure

Aluminium die casting molds, also known as dies or tooling, are crucial components in the process of aluminium die casting. Die casting is a manufacturing technique that involves injecting molten aluminium into a mold cavity under high pressure, allowing the material to solidify and form the desired shape.

The die casting mold plays a vital role in ensuring the accuracy, quality, and repeatability of the cast aluminium parts. It is typically made from high-quality steel, which is carefully machined and shaped to create the desired geometry of the final product. The mold consists of two halves, known as the "die halves," which come together to form the mold cavity.

Aluminium Die Casting Mould Tooling Parameters

| Brand Name: | Liushi |

| Tolerance: | ±0.03mm |

| Hardness: | Upon request |

| Mould size: | Customized size |

| Export region: | exporting mainly to Europe, America and Japan |

| Certificate: | ISO9001,National high-tech enterprises |

| Precision Machine | CNC machining center/Double heads of EDM machine/ optical curve grinder ect |

| Measuring Instruments: | Profile projector/ electronic height gauge/ 2D measuring instrument/ vernier caliper/ microscope/ micrometer ect |

| Cavity quantity: | Single, Multi Cavity, exchangeable Insert |

| Type of Plastic Material : | ABS, ABS+PC, PP, PS, POM, PVC, TPE, TPU, PA6,PA6.6+30GF,PPUS,PPS ,GPPS,etc. |

| Mould Life: | Depends on the material of steel |

| Professional customized processing accessories, injection molding plastic sample | |

Our Advantages

1. We are the biggest lost foam mould manufacturer in China, we focus on high challenge lost foam mould and we have large gantry machining centers,30 sets imported high speed machining center,more than 40 sets general machine tool equipment;

2. We have 36 senior mould designers, to ensure reasonable / safety / high efficiency mould design and ensure the fast mould delivery and rational mould structure, make the process more safer and the production efficiency more higher;

3. We using numerical control machine tool to manufacture the mould cavities, to ensure a even thickness ;

4. We using ZL104 Aluminium to casting the mould, to manufacture a high strength mould;

5. For the big mould, we using Ø22*1 copper tube as cooling pipe, with water spray system, to get a nice cooling effect;

6. We Have (TEF10N) coating on the mould surface, it can reduce the friction, anti water/static electricity/acid-base/high-temperature, with this we can ensure the pattern has smooth surface without distrotion, and easy to demould;

7. All the screws we using stainless steel screw, easy to disassemble during maintenance;

8. For the big mould chest, we using 18-20mm thick wrought aluminium plate, to offer high strenght cavity ;

9. For the complex mould which is difficult to demould, we can manufacture the automaitc mould with take out device ;

10. We produce the pattern sample to customer after finish the mould, when the pattern was qualified, then we do exceptance job for the mould ;