-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

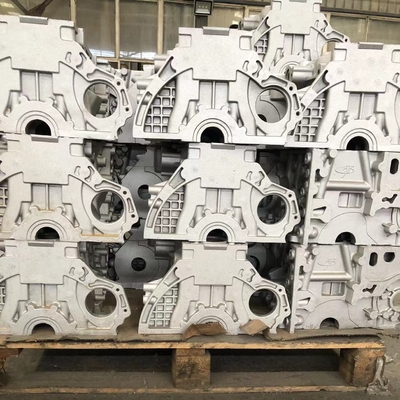

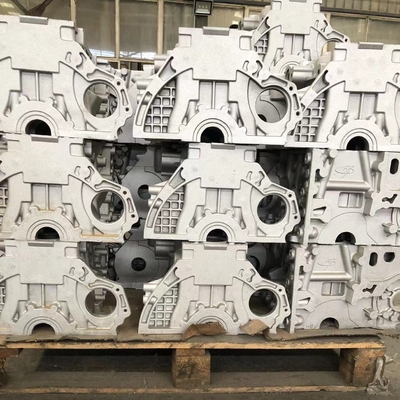

Customized Size Sandblasting Aluminum Alloy Casting For Automobile

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Inspection | 100% Inspection | Drawing Format | PDF, DWG, IGS, STP, Etc. |

|---|---|---|---|

| Tolerance | ±0.1mm-±0.5mm | Surface Treatment | Polishing, Sandblasting, Anodizing, Etc. |

| Application | Automotive, Aerospace, Etc. | Packaging | Wooden Cases, Cartons, Pallets, Etc. |

| Heat Treatment | Annealing, Quenching, Tempering, Etc. | Casting Method | Casting |

| Highlight | sandblasting aluminum alloy casting,automobile customized size aluminum alloy casting,sandblasting aluminium alloy die casting |

||

![]()

Product Description:

Aluminum Alloy Casting is a low pressure casting process that produces precise and reliable components with an excellent surface finish. Our aluminium alloy casting process produces components with tolerance up to ±0.1mm-±0.5mm, weight from 1-100kg and size customized according to customer requirements. Our casting process utilizes the highest grade aluminum alloy, and all components are 100% inspected, ensuring the highest quality product.

The aluminum alloy casting process provides an economical and efficient method to produce good quality components for a variety of applications. Our professional team is experienced in providing comprehensive services for the design and production of aluminium alloy components.

Our aluminium alloy casting process is suitable for a wide range of requirements and projects, from prototypes to production runs. We specialize in the aluminum alloy manufacturing process and are able to provide fast turnaround times and cost-effective solutions.

Features:

- Product Name: Aluminum Alloy Casting

- Application: Automotive, Aerospace, Etc.

- Tolerance: ±0.1mm-±0.5mm

- Material: Aluminum Alloy

- Surface Treatment: Polishing, Sandblasting, Anodizing, Etc.

- Heat Treatment: Annealing, Quenching, Tempering, Etc.

- Low Pressure Casting Processes

- Aluminium Alloy Manufacturing

- Gravity Casting Processes

Technical Parameters:

| Parameter | Value |

|---|---|

| Size | Customized |

| Tolerance | ±0.1mm-±0.5mm |

| Packaging | Wooden Cases, Cartons, Pallets, Etc. |

| Heat Treatment | Annealing, Quenching, Tempering, Etc. |

| Material | Aluminum Alloy |

| Application | Automotive, Aerospace, Etc. |

| Weight | 1-100kg |

| Inspection | 100% Inspection |

| Casting Method | Casting |

| Processing Technology | CNC Machining, Drilling, Milling, Turning, Etc. |

| Gravity Casting Process | Yes |

| Lost Foam Casting Process | Yes |

| Low Pressure Casting Process | Yes |

| Die Casting Process | Yes |

Applications:

Aluminum Alloy Casting produced by Liushi, with Place of Origin: Luoyang, is one of the most popular products. It has Certification: 16949, and Minimum Order Quantity: 1000 pcs. Payment Terms: TT is also acceptable. The Material used is Aluminum Alloy, and it is widely applied in Automotive, Aerospace and many other fields. The Processing Technologies include CNC Machining, Drilling, Milling, Turning and etc. The Weight of Aluminum Alloy Casting is from 1kg to 100kg. The Heat Treatment for it includes Annealing, Quenching, Tempering and etc. It is made by Lost Foam Casting Process, Aluminium Alloy Casting, Gravity Casting Process, Pressure Die Casting Process and Sand Casting Process.

Customization:

Brand Name: Liushi

Place of Origin: Luoyang

Certification: 16949

Minimum Order Quantity: 1000 pcs

Payment Terms: TT

Packaging: Wooden Cases, Cartons, Pallets, Etc.

Drawing Format: PDF, DWG, IGS, STP, Etc.

Application: Automotive, Aerospace, Etc.

Material: Aluminum Alloy

Tolerance: ±0.1mm-±0.5mm

Low Pressure Casting Processes, Aluminium Alloy Manufacturing, Gravity Casting Process.

Packing and Shipping:

Packaging and Shipping for Aluminum Alloy Casting:

Aluminum alloy castings are packed in wooden cases, lined with foam plastic, and sealed with plastic film. The package label should include product name, quantity, and weight. A wooden pallet should also be included for large orders. When handling and shipping, special care should be taken for fragile parts to prevent damage.