-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

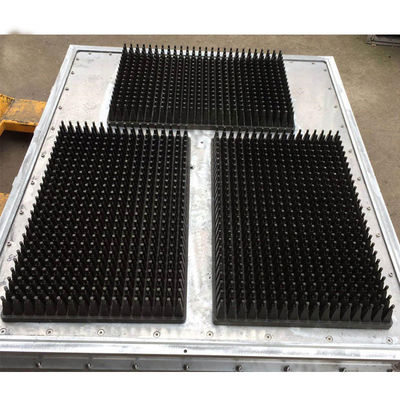

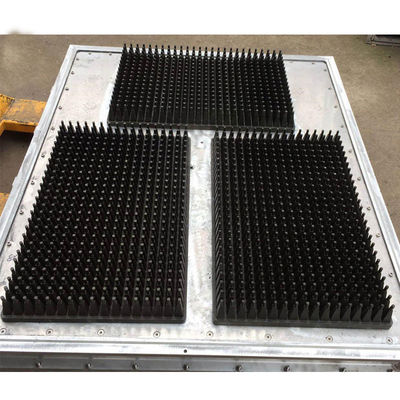

Customized EPS Mold Foam Box Mold For Making Fish Vegetable Fruit Box Made In China

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | EPS Foam Mould | Customized | Yes |

|---|---|---|---|

| Certification | ISO9001 | Service | OEM\ODM |

| Product Name | EPS Foam Mould |

|---|---|

| Customization | Yes |

| Certification | ISO9001 |

| Service | OEM/ODM |

We manufacture EPS moulds for various applications including electrical product packaging, boxes, EPS pallets, construction panels, and ICF systems.

Our EPS Foam Moulds are designed for operational efficiency with easy-opening mechanisms (manual or hydraulic), accessible vent cleaning points, simplified clamping systems, and clear part ejection mechanisms to minimize setup time and enhance production safety.

- Design based on customer drawings or samples

- ODM services with engineering support

- OEM manufacturing following client specifications

- Precision engineering for dimensional stability

- Easy assembly and disassembly

- Low maintenance requirements

- Extended service life

- High-quality surface finish

- Rugged and durable construction

| Size | Customized |

|---|---|

| Color | As per requirements |

| Material | Aluminum |

| Applications | Auto parts, light fixtures, lamp covers, LED light housings, heat sinks, and other die casting components |

- Quick mold change capability

- Easy cleaning and maintenance access

- Ergonomic operation design

- Enhanced safety features

- Reliable part ejection system

- Job shops with multiple product lines

- Operations with limited skilled labor

- Workplaces prioritizing safety and ergonomics

- Production requiring frequent mold changes

- Small manufacturers valuing operational simplicity

We offer flexible shipping options including air freight, sea freight, and expedited delivery services tailored to your timeline and budget requirements.

- China's largest lost foam mold manufacturer with advanced machining centers

- Team of 36 senior mold designers ensuring optimal design and fast delivery

- Precision CNC machining for uniform thickness

- ZL104 Aluminum construction for high strength

- Advanced cooling systems with copper tube and water spray

- TEF10N coating for reduced friction and easy demolding

- Stainless steel screws for easy maintenance

- Thick wrought aluminum plates for high-strength cavities

- Automated molds with take-out devices for complex designs

- Quality assurance with Hexagon coordinate measuring instruments

Luoyang Liushi Mould Co., Ltd, established in 2001, is the National Standard Setting Unit for Lost Foam Casting Mould. Located in Luoyang City, we operate from a 9,800 sqm office building and 22,000 sqm workshop equipped with comprehensive R&D, design, foundry, machining, and assembly facilities.

Our technicians provide on-site guidance for mold assembly, test production, and complete lost foam casting process technology. Committed to careful design, lean manufacturing, and perfect quality, we have become the preferred supplier for many lost foam casting manufacturers.